In the dynamic world of manufacturing, the role of advanced techniques in metal work and steel construction is crucial for achieving precision, efficiency, and quality. From industrial sheet metalwork to CNC cutting and laser cutting, each method contributes to creating durable and high-performance products.

- CNC Cutting: Utilizing computer-controlled machinery, CNC cutting offers unparalleled precision and repeatability. This technique allows for the creation of intricate patterns and designs, making it ideal for producing parts that require exact measurements.

- Laser Cutting: This process uses a high-powered laser to cut through metal sheets with exceptional accuracy. Laser cutting is valued for its ability to handle various metal thicknesses and produce clean, precise edges, which is critical for both aesthetic and functional components.

Mastering Metal Forming and Bending

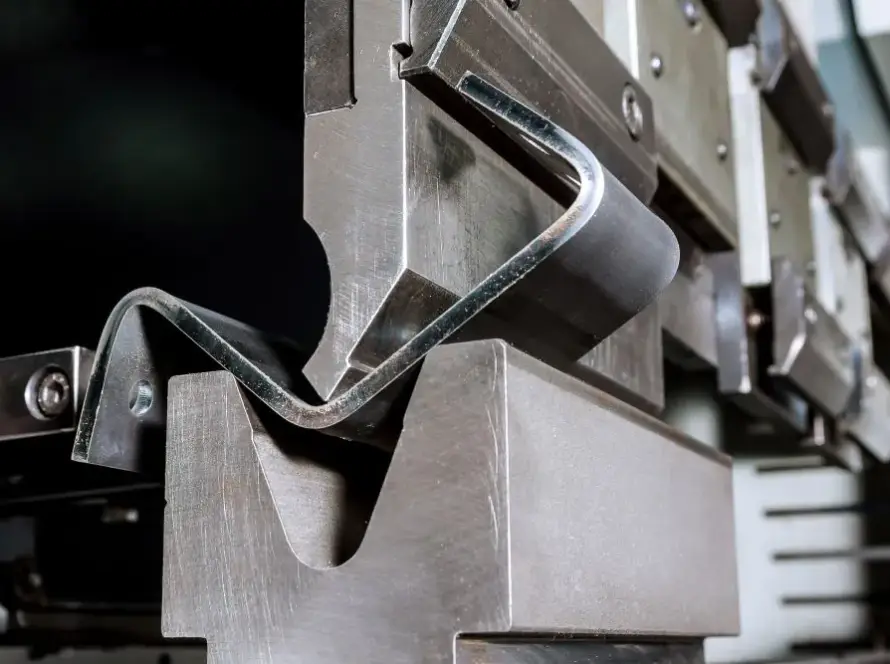

Metal bending and metal forming are integral to shaping metal into desired configurations. These techniques are used to produce parts that fit specific design requirements while maintaining structural integrity.

- CNC Bending: Using a CNC press brake, CNC bending allows for the precise bending of metal sheets into various angles and shapes. This method ensures consistent results and is essential for creating complex geometries and detailed components.

- Metal Forming: Metal forming encompasses a range of techniques, including stamping, rolling, and forging, to alter the shape of metal without removing material. This process is crucial for producing high-strength components and optimizing material usage.

Welding and Joining Techniques

Welding and joining are fundamental processes in steel construction and metal fabrication. These techniques are used to assemble components into finished structures, ensuring durability and strength.

- Welding: Various welding methods, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), are employed to join metal parts together. Welding provides strong, permanent bonds that are critical for the stability of structures and machinery.

- Profile Welding: This specialized form of welding focuses on joining metal profiles, such as beams and columns, used in steel construction. Profile welding ensures the integrity of large structural elements and is essential for building frameworks and supports.

- Pipe Laser: The pipe laser technique is used for precise cutting and alignment of pipes. This method enhances the accuracy of pipe fabrication and is crucial for applications in industries such as construction and manufacturing.

Integrating Project Design with Advanced Manufacturing Techniques

Successful manufacturing projects rely on effective project design to ensure that each component meets functional, aesthetic, and structural requirements. Advanced manufacturing techniques, including CNC cutting, laser cutting, and metal forming, are integrated into the design process to optimize production and achieve desired outcomes.

Project design involves creating detailed plans and specifications that guide the manufacturing process. By leveraging modern technologies and precise methods, designers can create efficient, high-quality products that meet client specifications and industry standards.

Precision and Innovation in Modern Manufacturing

The integration of advanced techniques such as industrial sheet metalwork, CNC cutting, laser cutting, CNC bending, and metal forming revolutionizes the manufacturing process, enhancing precision and efficiency. As technology continues to evolve, these methods play a crucial role in driving innovation in steel construction and metal fabrication.